News

News Industry News

Industry NewsSemiQ has added a set of full wave H-bridge modules to its silicon carbide (SIC) N-channel mosfet product portfolio. These components are designed specifically for triple threat applications that require high voltage, high-speed, and high-power components. They have been optimized for ultra-low switching losses, thereby improving efficiency and reducing power consumption. High efficiency, high junction temperature tolerance, and ceramic packaging can reduce heat dissipation and improve mechanical layout flexibility.

Ceramic packaging can directly install the heat sink on the insulation thermal pad. The electrical pin contacts are connected by through hole crimping, and the total area of the parts is 62.8 mm x 33.8 mm x 12 mm. Providing components in the complete H-bridge module can reduce assembly costs and reduce switch losses.

An important supplement to the professional product line

These five devices - GCMX020A120B2H1P, GCMX040A120B2H1P, GCMX080A120B2H1P, GCMX020A120B3H1P, and GCMX040A120B3H1P - all have a rated voltage of 1200 V, a breakdown voltage exceeding 1400 V, and a maximum junction temperature of 175C.

They all use the same ceramic pressure connection hole packaging. The maximum current capacity range of GCMX080A120B2H1P is 27 A, and the maximum current capacity of GCMX020A120B2H1P is 102 A. SemiQ has a wide range of high-power SiC device series, including discrete MOSFETs, Schottky diodes, and half bridge modules. Adding a complete H-bridge SiC module enables designers of high-power electronic products to reduce the number of parts, reduce product size, and achieve more efficient cooling.

When one MOSFET in the discrete H-bridge performs poorly, only the faulty part needs to be removed. In a module, a faulty component needs to discard the entire bridge. SemiQ recognizes this risk and reduces it through wafer level testing and aging. SemiQ uses these wafer level tests to ensure the gate oxide quality and stable gate threshold voltage of the entire module.

Aging and testing also evaluate gate stress, high temperature reverse bias drain stress, high humidity, high voltage, and high temperature reliability. The result is that automotive and industrial grade products have generous environmental space and a lower likelihood of early failures.

SiC MOSFETs demonstrate major advantages in DC applications

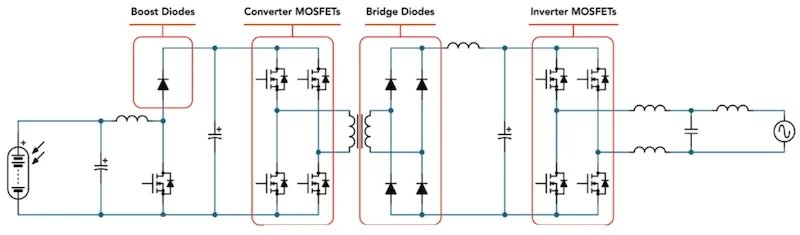

The new SiC MOSFET is suitable for power intensive DC applications, such as solar inverters, electric vehicle chargers, energy storage systems, and DC-DC converters. All of these applications require high voltage, high switching frequency, and high power capacity. SemiQ has designed a new product line specifically for high-power applications that require high switching frequency and high operating voltage efficiency.

Renewable energy and a large demand for server power belong to the DC field. Unfortunately, DC voltage conversion is much more complex than simple coupled inductor transformers used for AC power. DC voltage conversion requires a switch mode power supply (SMPS). If semiconductor materials can keep up, higher switching frequencies can provide better efficiency. SiC is one of the more durable materials than silicon. These components increase the efficiency of SMPS from the 90% range to the 98% range.

Solar inverter circuit

This is not just an 8% improvement. Switching loss is the cause of power waste and heat. In traditional semiconductors, the loss is about 10% of the current. The remaining 90% are currently processing applications. SiC delivers 90% of the loss and 80% of the loss. This means an 8% increase in current, but an 80% reduction in waste and heat.

Although direct current is used as the terminal power source for electronic devices, most electric vehicles still use AC motors because of their excellent efficiency. The operating voltage range of these motors is 300-600 V. If there were no such high voltage, the current consumption of a 50+kW motor would make the wiring, radiator, and motor too heavy to be practical. SiC devices, such as SemiQ's five new 1200V full bridge four way MOSFETs, can handle loads more effectively than standard silicon.

If you are interested in SiC module devices or need to learn more about related application information, please bookmark our Faust Technology. Here, you will be the first to receive the latest news from SemiQ and connect with the future peers of semiconductor technology.