News

News Industry News

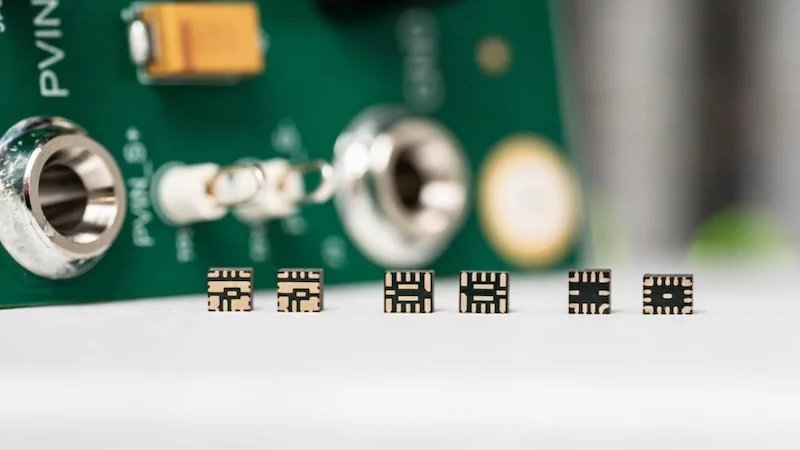

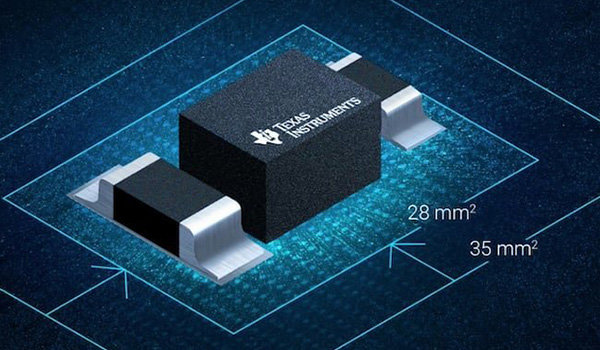

Industry NewsTexas Instruments (TI) has launched the MagPack component package, which includes six power magnetic modules. According to reports, this series is 50% smaller than TI's previous generations and 23% smaller than competitors' current generation modules. In addition to size, the MagPack package can also reduce 8 dB EMI and increase efficiency by 2%.

The MagPack power module includes an internal inductor that occupies an area of 6.9 square millimeters or less, while providing up to 6 A of current at 5.5 V output. This makes the component the "world's smallest 6 A, 5 V power module", providing nearly 1 A of current per 1 square millimeter of PC board space.

MagPack technology will help designers reduce product size and weight while maintaining critical power delivery. TI has designed power modules for optical, medical electronics, industrial control, aerospace, and defense applications.

Power supplies are usually not dominant in electronic products, but they can quickly create or destroy a product like any design part. These MagPack based power modules allow engineers to spend less time optimizing the power supply, leaving more time for the rest of the circuit.

Breakthrough in Design and Packaging

TI has achieved this performance through efficient electrical design and packaging, specifically, lower junction to environment resistance (R Ө JA) than old technology packaging. R Ө JA is the speed at which heat is transferred from the silicon junction to the surrounding air. The MagPack module abandoned internal bonding wires to optimize internal wiring. Both of these factors improved R Ө JA and reduced parasitic resistance and inductance. The dedicated lead frame improves the heat transfer from the module to the PC board.

Internal inductors are matched with silicon wafers to improve AC and DC loss coefficients. Inductors are one of the most critical components in efficient power supply design, but they are also one of the most difficult components to match and obtain. Integrating this difficult component can shorten design time, alleviate supply chain burden, and reduce the number of manufactured parts.

Roja de Cande, Product Line Manager at TI, said, "Innovative packaging is completely reshaping our industry, and we believe this is the key to the next frontier of power innovation

Input and output capacitors are not critical components, therefore they are not built-in, providing greater flexibility in selection and placement. According to Anton Winkler, a system engineer and power module technology expert at TI, inductors pose greater challenges for power designers than input and output capacitors.

Sometimes it's easy for customers to place these [input and output] capacitors because they already have a lot on their circuit board, such as ten microfarads of capacitors, so it's already part of the BOM, "Winkler said. But for inductors, this is a bit difficult. They may require a special component for dedicated converters

TI installs the inductor around the silicon wafer and embeds it into the package. Winkler explained that the inductor is formed around the entire silicon wafer and packaged together. Surrounding the silicon wafer with inductors helps improve EMI performance without compromising on inductor selection or commissioning custom designs.

Winkler said, "TI's new MagPack packaging technology is fundamentally different because there is no similar technology on the market yet

MagPack Series Segmentation

The operating efficiency of this module is as high as 96%. They have integrated soft start circuits that can reduce surge currents, as well as overheat protection and intermittent short circuit protection. They require very few external components, only input and output capacitors and resistors.

Fushite Technology focuses on the field of power devices, providing customers with power devices such as IGBT and IPM modules, as well as MCU and touch chips. It is an electronic component supplier and solution provider with core technology.