News

News Industry News

Industry NewsToshiba recently announced a new non isolated DC-DC converter technology that operates within a voltage range of 48 volts to 1 volt. These devices solve the problem of conduction losses caused by increased demand for servers and data centers, which increases the load current in DC-DC converters. Higher load current and conduction loss will generate heat and reduce overall efficiency.

In order to reduce these losses, industry standards have raised the input voltage from 12 volts to 48 volts. This reduces the current at a given power level, thereby reducing conduction losses. However, this transformation has also brought new challenges to the design of DC-DC converters, especially in terms of step-down topology.

Toshiba claims that its new star delta switch topology achieves the industry's highest current density while eliminating the need for transformers for DC-DC converter ICs with 48 volt input and 1 volt output.

Toshiba utilizes star delta switch topology

At the 2024 IEEE VLSI Technology and Circuit Symposium, Toshiba showcased its new 48V to 1V non isolated DC-DC converter technology. The testing equIPMent achieved a current density of up to 790 mA/mm ² and a power conversion efficiency of up to 88%.

According to Toshiba, its star delta switch topology eliminates the need for transformers typically used in isolation topologies to manage pulse width extension. On the contrary, Toshiba uses a hybrid configuration of inductors and capacitors, carefully controlled by FETs, significantly reducing the volume and quantity of external components. Toshiba claims that its star delta topology reduces the number of capacitors per pulse width spread ratio from 0.8 to 1.0 to 0.5 to 0.6.

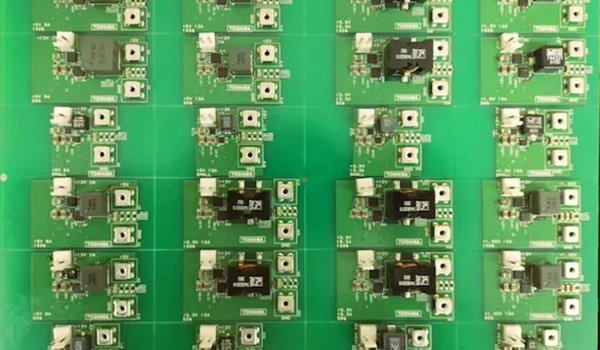

Toshiba demonstrated the effectiveness of this topology through a series of test chips. The company has developed a bootstrap circuit that reduces layout area by up to 61%, as well as a level converter circuit that supports an active bias current scheme, reducing bias current by up to 92%.

Eliminate the volume of transformers and capacitors

In a buck converter, the pulse width of the driving power switch must be four times shorter than 12 volts to boost the input voltage to 48 volts. This reduced pulse width increases switch losses as transitions between on and off states become more frequent and less efficient. These switch losses directly reduce the overall power conversion efficiency of the system.

Designers typically use transformers in isolated topologies to address these efficiency issues. Transformers can expand pulse width and prevent switching losses, but they also add significant volume to the design, which is a problem in space limited applications.

Non isolated hybrid topology is a compact alternative solution. These designs use a combination of inductors and capacitors to manage pulse width extension without the need for bulky transformers. Compared to transformer based solutions, this method can reduce the total volume of the converter by 10 to 100 times. Despite its space saving advantages, hybrid topology also brings its own challenges.

A significant drawback is the need for a large number of capacitors - typically 0.8 to 1.0 capacitors per pulse width spread ratio. The increased number of capacitors leads to higher external component density and crowded pin wiring, complicating PCB layout and increasing installation costs. The additional capacitors and complex wiring increase manufacturing costs and pose challenges to the reliability and maintenance of the system.